Bloga

Exploring Siemens CNC Control Features and Benefits

In today’s fast-paced manufacturing world, the need for efficiency and precision has never been more critical. As industries strive to meet increasing demands while maintaining high standards, Siemens CNC control systems have emerged as a cornerstone in achieving these goals. These systems are not just tools; they are comprehensive solutions that enhance productivity and accuracy across various manufacturing processes. Whether you’re new to CNC programming or a seasoned professional, gaining a deep understanding of the features and benefits of Siemens CNC control can profoundly impact your operations. This article delves into the multifaceted aspects of Siemens CNC control, its advanced automation capabilities, and how it can streamline and optimize your manufacturing processes.

Siemens CNC control systems are sophisticated computer numerical control systems designed to operate machine tools and manage manufacturing processes with precision and efficiency. These systems have become an integral component of modern manufacturing, offering unparalleled control over machining tasks. Siemensa, a global leader in automation and digitalization, has engineered CNC control systems that are both versatile and user-friendly, making them the preferred choice for a wide range of industries, from automotive to aerospace and beyond.

The adaptability of Siemens CNC systems allows them to fit seamlessly into diverse manufacturing environments. They are designed to cater to the needs of both small-scale workshops and large industrial facilities, providing solutions that scale according to specific requirements. This adaptability ensures that businesses can maintain a competitive edge in a rapidly changing market, leveraging Siemens’ commitment to innovation and technological excellence.

Key Features of Siemens CNC Control

Siemens CNC control systems are equipped with a suite of features specifically designed to optimize the manufacturing process. Below are some of the key features that set them apart:

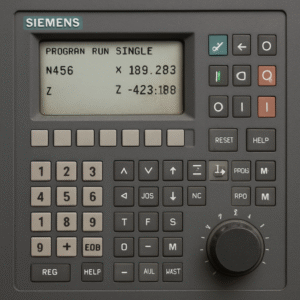

- User-Friendly Interface: The intuitive interface of Siemens CNC systems simplifies machine programming and operation, reducing the learning curve for operators. This ease of use allows operators to concentrate on production efficiency rather than being bogged down by complex programming tasks. The streamlined interface is crucial for minimizing errors and ensuring smooth operation in high-pressure environments.

- Advanced Programming Capabilities: Siemens CNC systems excel in handling complex machining operations with ease. They support multiple programming languages, offering flexibility and adaptability in diverse manufacturing settings. This capability enables manufacturers to execute intricate designs and modifications swiftly, enhancing their ability to innovate and meet specific client needs.

- High Precision and Accuracy: Renowned for their precision, Siemens CNC control systems ensure that every machining action—be it cutting, drilling, or turning—is executed with the utmost accuracy. This precision is vital for maintaining quality standards, reducing waste, and minimizing the need for rework, thus ensuring that every product meets stringent quality criteria.

- Real-Time Monitoring: A standout feature of Siemens CNC control is its real-time monitoring capability. This allows operators to track the progress of machining tasks, identify potential issues, and make real-time adjustments to reduce downtime and enhance productivity. The ability to monitor processes as they happen provides a significant advantage in maintaining efficiency and preventing costly delays.

Benefits of Using Siemens CNC Control

Implementing Siemens CNC control in manufacturing operations offers numerous benefits that extend beyond mere operational efficiency. Here, we explore some of the most significant advantages:

Enhanced Productivity

Siemens CNC control systems are designed to streamline the manufacturing process, significantly reducing the time required for setup and execution. The robust automation capabilities of these systems allow for continuous operation with minimal human intervention, thereby maximizing output. This increase in productivity translates to faster turnaround times, allowing manufacturers to meet tight deadlines and improve overall profitability. The abil

ity to automate routine tasks frees up skilled personnel to focus on more strategic initiatives, further enhancing productivity.

Improved Quality and Consistency

With Siemens CNC control, manufacturers can achieve a level of consistency in quality that is difficult to replicate manually. The system’s precision ensures that each part produced adheres to exact specifications, thereby reducing the risk of errors and the need for rework. Consistency in production is crucial for maintaining customer satisfaction, as clients expect uniformity in the products they receive. By delivering high-quality, consistent products, manufacturers can build a strong reputation and foster long-term customer loyalty.

Cost Savings

Automation of machining processes through Siem

ens CNC control systems leads to significant cost savings by reducing reliance on manual labor. This reduction in labor costs is complemented by the system’s efficiency in minimizing material waste, further decreasing operational expenses. The precision and accuracy of Siemens CNC systems also reduce the likelihood of costly errors and rework, ensuring that resources are used optimally. Nadgodziny, these savings contribute to a healthier bottom line, enabling businesses to reinvest in growth and innovation.

Flexibility and Scalability

Siemens CNC systems are highly adaptable, making them ideal for a wide array of applications. Whether managing a small workshop or overseeing a large manufacturing facility, Siemens CNC control can scale to meet your operational needs. The system’s flexibility allows for seamless integration with existing processes and technologies, ensuring a smooth transition and ongoing compatibility with evolving manufacturing demands. This adaptability is key for businesses looking to expand their capabilities and explore new markets without the need for significant infrastructure changes.

Siemens Automation: Taking CNC to the Next Level

Siemens is not only a leader in CNC control but also a pioneer in automation technology. The synergy between Siemens CNC systems and their automation solutions provides a comprehensive approach to achieving manufacturing efficiency.

Integration with Siemens Automation

The integration of Siemens CNC control systems with Siemens automation technologies creates a fully automated manufacturing environment. This integration facilitates seamless data exchange between machines and systems, enhancing coordination and optimi

zing the entire production process. By linking CNC systems with automation technologies, manufacturers can achieve a level of process harmony that boosts efficiency and minimizes errors. This synergy allows for real-time adjustments and data-driven decision-making, enabling manufacturers to respond swiftly to production challenges.

Benefits of Siemens Automation Integration

- Increased Efficiency: Automating repetitive tasks with Siemens automation technology reduces the burden on human operators, allowing them to focus on more complex, value-added activities that require human judgment and expertise. This shift not only improves operational efficiency but also enhances employee satisfaction by freeing them from monotonous tasks.

- Enhanced Data Management: Siemens automation solutions offer robust data management capabilities, empowering manufacturers to collect, analyze, and leverage data for informed decision-making. This data-driven approach allows for the optimization of operations, identification of trends, and anticipation of potential issues before they escalate, thus improving overall operational effectiveness.

- Greater Flexibility: Automation provides the agility needed to make quick adjustments to production schedules and processes. This flexibility enables manufacturers to respond swiftly to changes in demand, ensuring that production output aligns with market needs. By maintaining this level of responsiveness, businesses can capitalize on new opportunities and mitigate the risks associated with fluctuating demand.

CNC Programming with Siemens: Simplifying Complexity

Siemens CNC control systems are engineered to simplify CNC programming, making it accessible to operators across all skill levels. Whether you’re just starting or are an experienced programmer, Siemens provides the tools and resources necessary to succeed.

Intuitive Programming Tools

Siemens offers a comprehensive suite of programming tools designed to simplify the creation of complex machining programs. These tools provide step-by-step guidance, reducing the likelihood of errors and enhancing the efficiency of the programming process. By streamlining program creation, Siemens empowers operators to focus on precision and innovation rather than being bogged down by technical complexities.

Comprehensive Training and Support

Siemens is dedicated to supporting its users through extensive training programs and resources. These programs are designed to help operators master CNC programming and maximize the potential of their systems. By offering ongoing support and education, Siemens ensures that manufacturers can fully leverage the capabilities of their CNC control systems, driving both short-term success and long-term growth.

Wniosek

Siemens CNC control systems are an invaluable asset for any manufacturing operation, offering advanced features, integration capabilities, and robust support for automation. These systems not only enhance productivity, quality, and efficiency but also provide the tools necessary to stay ahead in a rapidly evolving industry. By choosing Siemens CNC control, manufacturers position themselves to meet the demands of the market, ensuring competitive advantage and sustained success. Whether you’re new to CNC programming or looking to upgrade your existing setup, Siemens CNC control offers the comprehensive solutions and support you need to excel in today’s competitive manufacturing landscape.