Blog

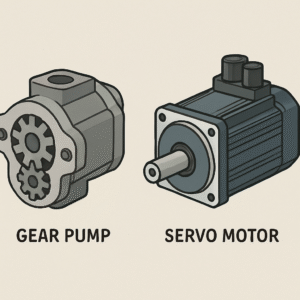

Any idea how to take out gear pump from the servo motor

Removing a gear pump from a servo motor can seem daunting, but with the right tools and guidance, it becomes a manageable task. This guide aims to provide a clear, step-by-step approach to disassemble a gear pump from a servo motor. Whether you’re facing a gear pump stuck issue, or need to perform routine maintenance, this guide will assist you in troubleshooting and safely removing the gear pump.

Before diving into the disassembly process, it’s crucial to understand the relationship between gear pumps and servo motors. A gear pump uses gears to pump fluid by displacement, and it is commonly used in hydraulic systems. Servo motors, on the other hand, are used to precisely control the position, velocity, and acceleration of the pump.

Common Reasons for Gear Pump Removal

There are several reasons why you might need to remove a gear pump from a servo motor:

- Routine maintenance or inspection.

- Repair or replacement due to wear and tear.

- Troubleshooting and fixing a gear pump stuck issue.

- Upgrading to a more efficient system.

Understanding these reasons can help you determine the urgency and approach required for disassembly.

Essential Tools and Safety Precautions

Before you begin, gather the necessary tools:

- Wrenches and screwdrivers

- Allen keys

- Rubber mallet

- Lubricants

- Protective gloves and eyewear

Safety should be your top priority. Always ensure the system is powered off and depressurized before starting. Wear appropriate protective equipment to prevent injury.

Step-by-Step Guide to Disassemble a Gear Pump

1. Preparing the System

Start by disconnecting the power supply to the servo motor. Ensure that the hydraulic system is depressurized to avoid any sudden release of fluid. Clean the area around the gear pump to prevent debris from entering the system during disassembly.

2. Disconnecting the Hydraulic Lines

Carefully disconnect the hydraulic lines attached to the gear pump. Use a container to catch any residual fluid that may leak during this process. Label the lines if necessary to ensure proper reassembly.

3. Removing the Mounting Bolts

Use the appropriate wrench to remove the bolts that secure the gear pump to the servo motor. It’s important to loosen the bolts gradually in a crisscross pattern to prevent any undue stress on the components.

4. Detaching the Gear Pump

Gently tap the gear pump with a rubber mallet if it appears stuck. Avoid using excessive force, as this can damage the pump or motor. Once loosened, carefully slide the gear pump away from the servo motor.

5. Inspecting the Components

With the gear pump removed, inspect it for any signs of wear or damage. Check the gears, housing, and seals for wear and tear. If any components are damaged, consider repairing or replacing them before reassembly.

Troubleshooting Common Issues

Gear Pump Stuck Issue Fix

If the gear pump is difficult to remove, it may be due to corrosion or misalignment. Applying a penetrating lubricant around the mounting area can help loosen the pump. If corrosion is present, gently clean the area with a wire brush before attempting removal.

Hydraulic Gear Pump Disassembly

For those needing to further disassemble the gear pump itself, consult the manufacturer’s manual for specific instructions. Typically, this involves removing additional screws and separating the gear housing to access the internal components.

Reinstallation and Testing

After addressing any issues, reassemble the gear pump to the servo motor by reversing the removal steps. Ensure all bolts are tightened securely, and hydraulic lines are reconnected correctly. Test the system to verify that it operates smoothly and without leaks.

Tips for Successful Gear Pump Maintenance

Regular maintenance can extend the life of your gear pump and prevent future issues:

- Schedule routine inspections and cleanings.

- Monitor for unusual noises or vibrations during operation.

- Replace worn seals and gaskets promptly to prevent leaks.

- Keep detailed records of maintenance and repairs for future reference.

Conclusion

Removing a gear pump from a servo motor requires patience and attention to detail. By following this guide, you should be able to perform the disassembly safely and efficiently. Remember, regular maintenance and proper handling are key to ensuring the longevity and reliability of your hydraulic system. If you’re ever unsure, consult a professional to avoid damaging your equipment.