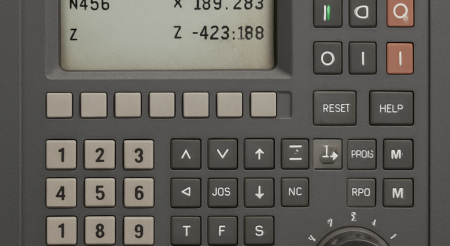

In today’s fast-paced manufacturing world, the need for efficiency and precision has never been more critical. As industries strive to meet increasing demands while maintaining high standards, Siemens CNC control systems have emerged as a cornerstone in achieving these goals. These systems are not just tools; they are comprehensive solutions that enhance productivity and accuracy across various manufacturing processes. Whether you’re new to CNC programming or a seasoned professional, gaining a deep understanding of the features and benefits of Siemens CNC control can profoundly impact your operations. This article delves into the multifaceted aspects of Siemens CNC control, its advanced automation capabilities, and how it can streamline and optimize your manufacturing processes. Siemens CNC control systems are sophisticated computer numerical control systems designed to operate machine tools and manage manufacturing processes with precision and efficiency. These systems have become an integral component of modern manufacturing, offering unparalleled control over machining tasks. Siemens, a global leader in automation and digitalization, has engineered CNC control systems that are both versatile and user-friendly, making them the preferred choice for a wide range of industries, from automotive to aerospace and beyond. The adaptability of Siemens CNC systems allows them to fit seamlessly into diverse manufacturing environments. They are designed to cater to the needs of both small-scale workshops and large industrial facilities, providing solutions that scale according to specific requirements. This adaptability ensures that businesses can maintain a competitive edge in a rapidly changing market, leveraging Siemens’ commitment to innovation and technological excellence. Key Features of Siemens CNC Control Siemens CNC control systems are equipped with a suite of features specifically designed to optimize the manufacturing process. Below are some of the key features that set them apart: User-Friendly Interface: The intuitive interface of Siemens CNC systems simplifies machine programming and operation, reducing the learning curve for operators. This ease of use allows operators to concentrate on production efficiency rather than being bogged down by complex programming tasks. The streamlined interface is crucial for minimizing errors and ensuring smooth operation in high-pressure environments. Advanced Programming Capabilities: Siemens CNC systems excel in handling complex machining operations with ease. They support multiple programming languages, offering flexibility and adaptability in diverse manufacturing settings. This capability enables manufacturers to execute intricate designs and modifications swiftly, enhancing their ability to innovate and meet specific client needs. High Precision and Accuracy: Renowned for their precision, Siemens CNC control systems ensure that every machining action—be it cutting, drilling, or turning—is executed with the utmost accuracy. This precision is vital for maintaining quality standards, reducing waste, and minimizing the need for rework, thus ensuring that every product meets stringent quality criteria. Real-Time Monitoring: A standout feature of Siemens CNC control is its real-time monitoring capability. This allows operators to track the progress of machining tasks, identify potential issues, and make real-time adjustments to reduce downtime and enhance productivity. The ability to monitor processes as they happen provides a significant advantage in maintaining efficiency and preventing costly delays. Benefits of Using Siemens CNC Control Implementing Siemens CNC control in manufacturing operations offers numerous benefits that extend beyond mere...

En savoir plus