PLC Meaning – The Core Definition What does PLC stand for? PLC means Programmable Logic Controller (sometimes simply called a Programmable Controller). It’s a rugged... Continue reading

Menu

Catégories

In today’s fast-paced world, robotics and automation are at the heart of transformative changes that drive efficiency, innovation, and competitive edge across a multitude of... Continue reading

In today’s world, where electricity powers almost every aspect of daily life, ensuring the reliability and safety of electrical systems is crucial. Siemens breakers are a well-regarded choice for those seeking dependable and efficient solutions for electrical circuit protection. Known for their robust construction and advanced technology, Siemens breakers have become a staple in both residential and commercial settings. This article delves into the features and benefits of Siemens breakers, shedding light on why they are a trusted name in the electrical industry and a preferred choice for electricians and homeowners alike. Siemens breakers are sophisticated devices engineered to safeguard electrical circuits from potential damage caused by overloads and short circuits. These breakers function by automatically... Continue reading

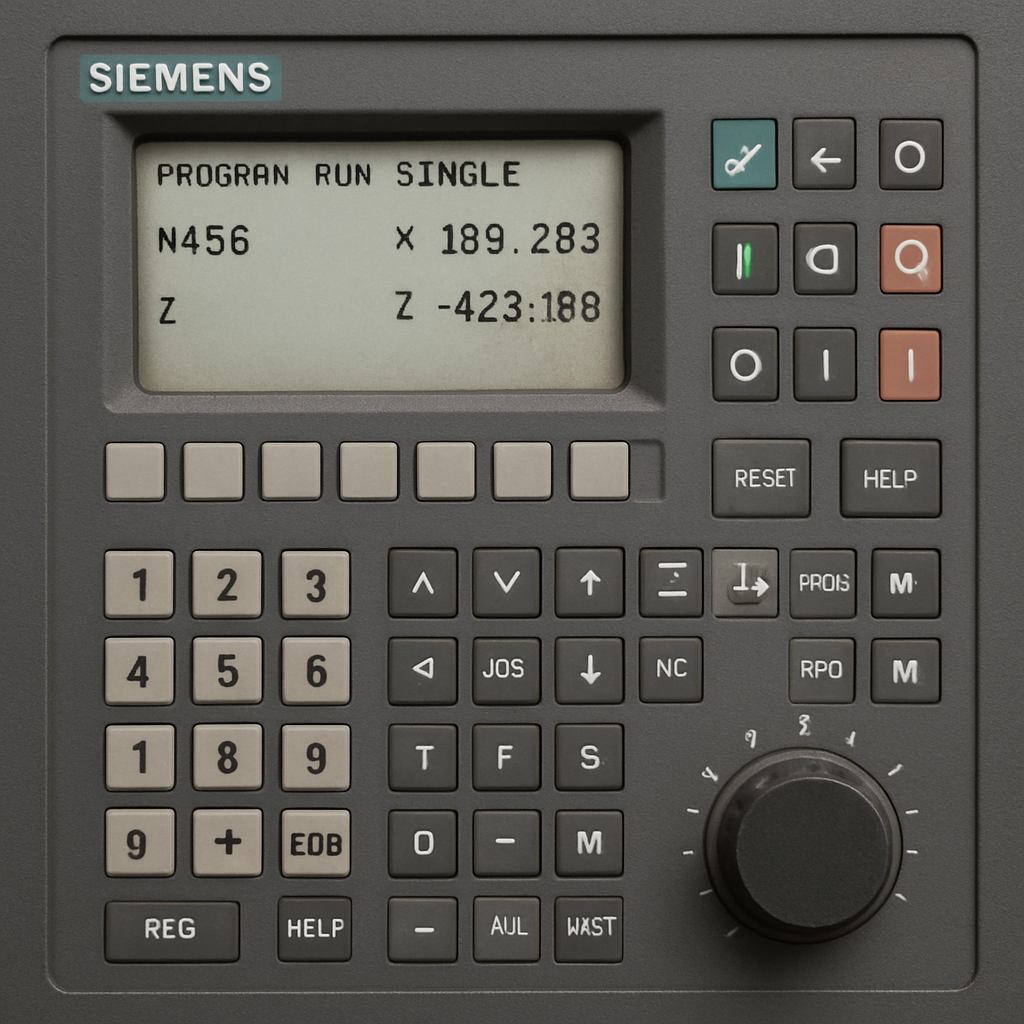

In today’s fast-paced manufacturing world, the need for efficiency and precision has never been more critical. As industries strive to meet increasing demands while maintaining high standards, Siemens CNC control systems have emerged as a cornerstone in achieving these goals. These systems are not just tools; they are comprehensive solutions that enhance productivity and accuracy across various manufacturing processes. Whether you’re new to CNC programming or a seasoned professional, gaining a deep understanding of the features and benefits of Siemens CNC control can profoundly impact your operations. This article delves into the multifaceted aspects of Siemens CNC control, its advanced automation capabilities, and how it can streamline and optimize your manufacturing processes. Siemens CNC control systems are sophisticated computer numerical control systems designed to operate machine tools and manage manufacturing processes with precision and efficiency. These systems have become an integral component of modern manufacturing, offering unparalleled control over machining tasks. Siemens, a global leader in automation and digitalization, has engineered CNC control systems that are both versatile and user-friendly, making them the preferred choice for a wide range of industries, from automotive to aerospace and beyond. The adaptability of Siemens CNC systems allows them to fit seamlessly into diverse manufacturing environments. They are designed to cater to the needs of both small-scale workshops and large industrial facilities, providing solutions that scale according to specific requirements. This adaptability ensures that businesses can maintain a competitive edge in a rapidly changing market, leveraging Siemens’ commitment to innovation and technological excellence. Key Features of Siemens CNC Control Siemens CNC control systems are equipped with a suite of features specifically designed to optimize the manufacturing process. Below are some of the key features that set them apart: User-Friendly Interface: The intuitive interface of Siemens CNC systems simplifies machine programming and operation, reducing the learning curve for operators. This ease of use allows operators to concentrate on production efficiency rather than being bogged down by complex programming tasks. The streamlined interface is crucial for minimizing errors and ensuring smooth operation in high-pressure environments. Advanced Programming Capabilities: Siemens CNC systems excel in handling complex machining operations with ease. They support multiple programming languages, offering flexibility and adaptability in diverse manufacturing settings. This capability enables manufacturers to execute intricate designs and modifications swiftly, enhancing their ability to innovate and meet specific client needs. High Precision and Accuracy: Renowned for their precision, Siemens CNC control systems ensure that every machining action—be it cutting, drilling, or turning—is executed with the utmost accuracy. This precision is vital for maintaining quality standards, reducing waste, and minimizing the need for rework, thus ensuring that every product meets stringent quality criteria. Real-Time Monitoring: A standout feature of Siemens CNC control is its real-time monitoring capability. This allows operators to track the progress of machining tasks, identify potential issues, and make real-time adjustments to reduce downtime and enhance productivity. The ability to monitor processes as they happen provides a significant advantage in maintaining efficiency and preventing costly delays. Benefits of Using Siemens CNC Control Implementing Siemens CNC control in manufacturing operations offers numerous benefits that extend beyond mere... Continue reading

In today’s rapidly evolving industrial landscape, automation is at the forefront of driving efficiency, productivity, and innovation. Siemens Logo Automation Parts play a crucial role... Continue reading

Chez DUOMI CNC, we specialize in providing high-quality automation equipment parts, including Sew Eurodrive inverters, to over 100 countries worldwide. Whether you are in need... Continue reading

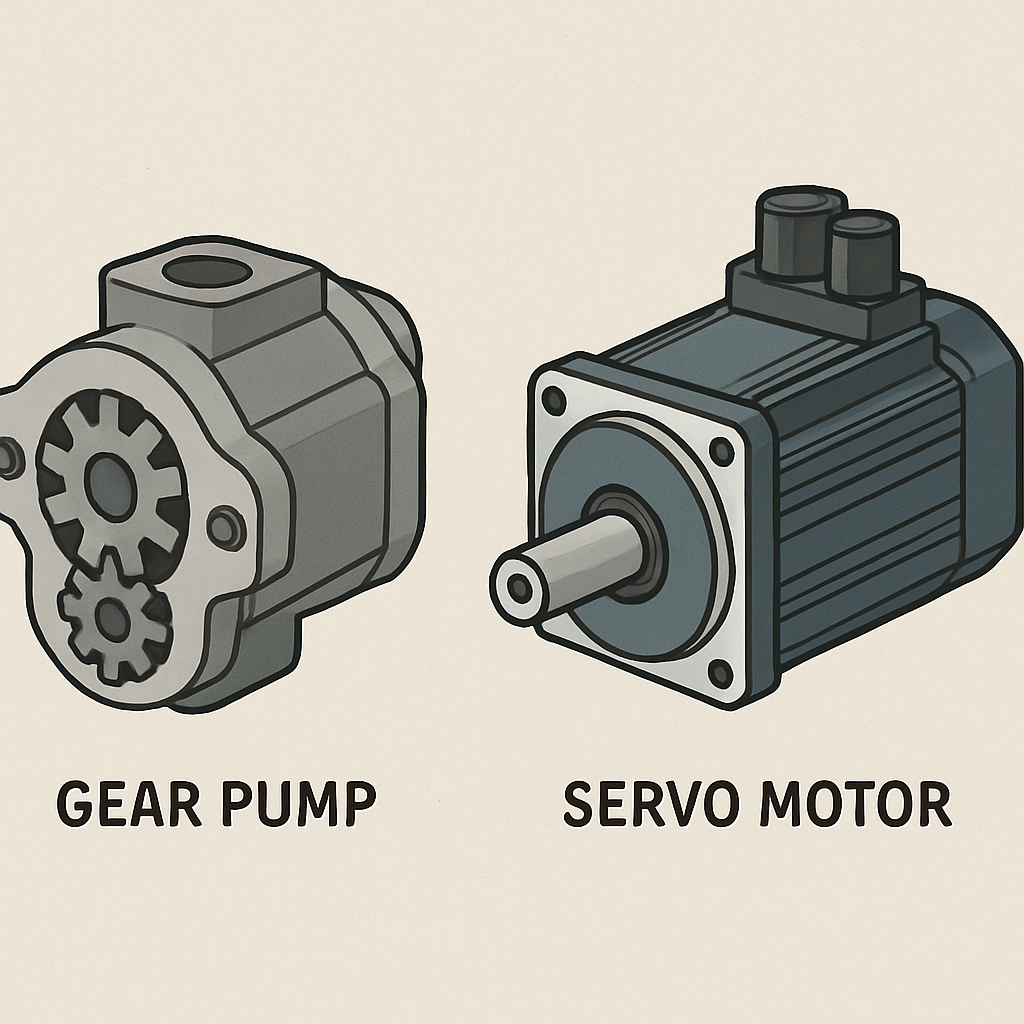

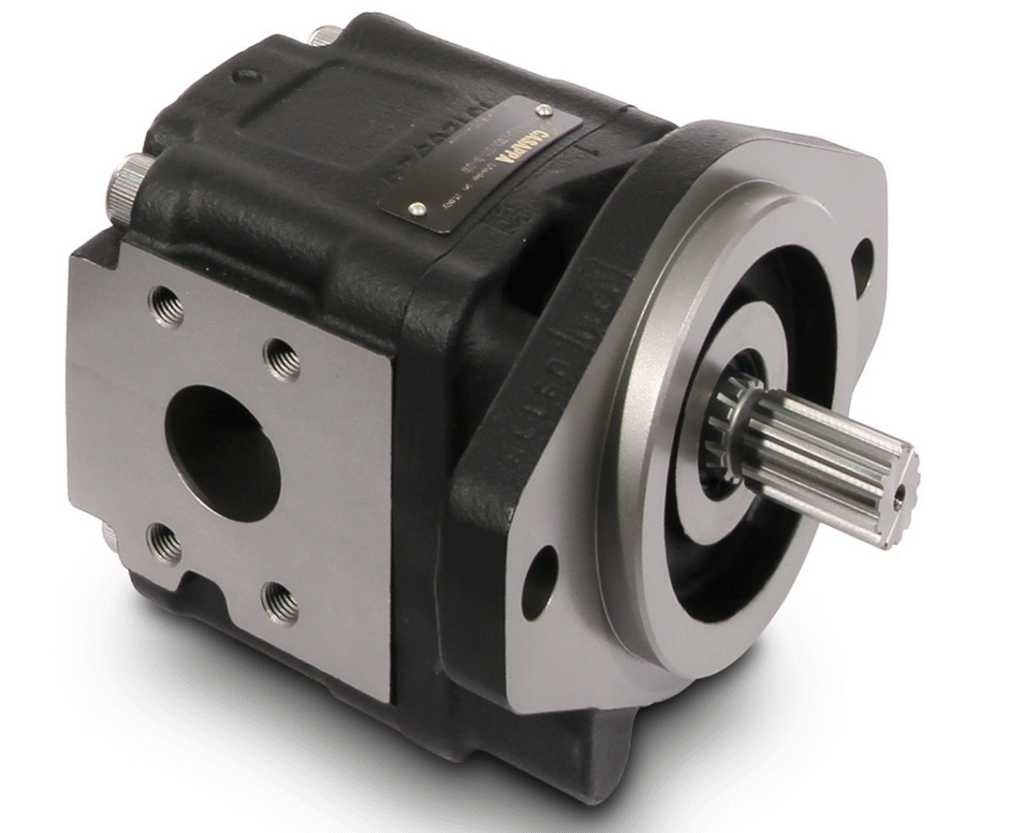

Removing a gear pump from a servo motor can seem daunting, but with the right tools and guidance, it becomes a manageable task. This guide aims to provide a clear, step-by-step approach to disassemble a gear pump from a servo motor. Whether you’re facing a gear pump stuck issue, or need to perform routine maintenance, this guide will assist you in troubleshooting and safely removing the gear pump. Before diving into the disassembly process, it’s crucial to understand the relationship between gear pumps and servo motors. A gear pump uses gears to pump fluid by displacement, and it is commonly used in hydraulic systems. Servomoteurs, on the other hand, are used to precisely control the position, velocity, and acceleration of the pump. Common Reasons for Gear Pump Removal There are several reasons why you might need to remove a gear pump from a servo motor: Routine maintenance or inspection. Repair or replacement due to wear and tear. Troubleshooting and fixing a gear pump stuck issue. Upgrading to a more efficient system. Understanding these reasons can help you determine the urgency and approach required for disassembly. Essential Tools and Safety Precautions Before you begin, gather the necessary tools: Wrenches and screwdrivers Allen keys Rubber mallet Lubricants Protective gloves and eyewear Safety should be your top priority. Always ensure the system is powered off and depressurized before starting. Wear appropriate protective equipment to prevent injury. Step-by-Step Guide to Disassemble a Gear Pump 1. Preparing the System Start by disconnecting the power supply to the servo motor. Ensure that the hydraulic system is depressurized to avoid any sudden release of fluid. Clean the area around the gear pump to prevent debris from entering the system during disassembly. 2. Disconnecting the Hydraulic Lines Carefully disconnect the hydraulic lines attached to the gear pump. Use a container to catch any residual fluid that may leak during this process. Label the lines if necessary to ensure proper reassembly. 3. Removing the Mounting Bolts Use the appropriate wrench to remove the bolts that secure the gear pump to the servo motor. It’s important to loosen the bolts gradually in a crisscross pattern to prevent any undue stress on the components. 4. Detaching the Gear Pump... Continue reading

Outils et matériaux dont vous aurez besoin avant de commencer à retirer la pompe à engrenages de votre servomoteur, rassembler ces outils et matériaux essentiels: Outils à main de base:... Continue reading

Understanding Inverter Voltage Fluctuation Causes Inverter voltage fluctuation is a common issue in many households. Cela peut endommager les appareils électriques et causer des désagréments. Comprendre les causes de ces fluctuations est crucial pour les propriétaires comme pour les électriciens.. Les fluctuations de tension peuvent résulter de divers facteurs. Mauvais câblage, circuits surchargés, et les onduleurs défectueux sont des coupables courants. Les conditions environnementales comme la température et l’humidité jouent également un rôle. Un entretien régulier des systèmes électriques peut aider à prévenir ces problèmes. Il est essentiel de s'assurer que les onduleurs sont correctement dimensionnés pour la charge.. Cela peut réduire considérablement le risque de fluctuations de tension. Dans ce guide, nous explorerons les causes de la fluctuation de la tension de l'onduleur. Nous fournirons également des solutions pour atténuer efficacement ces problèmes.. Qu'est-ce que la fluctuation de tension de l'onduleur? La fluctuation de la tension de l'onduleur fait référence aux changements irréguliers de la tension de sortie d'un onduleur.. Ces fluctuations peuvent affecter les performances des appareils électriques connectés à l'onduleur. Comprendre les causes de ces fluctuations est essentiel pour trouver des solutions. Plusieurs facteurs contribuent à la fluctuation de la tension de l'onduleur, y compris: Improper inverter sizing Environmental conditions Overloaded circuits Inverters are designed to provide a steady voltage output, mais quand ils échouent, cela peut conduire à une alimentation en tension incohérente. Cette incohérence peut créer des problèmes tels que des lumières scintillantes ou des performances intermittentes des appareils.. La surveillance des niveaux de tension permet d'identifier les fluctuations. Utiliser un multimètre, vous pouvez mesurer la tension pour vous assurer qu'elle se situe dans les limites normales. Diagnostiquer les fluctuations à un stade précoce peut éviter des problèmes plus graves à l'avenir.. Common Voltage Fluctuation Causes in Inverters Inverters are crucial for converting DC power to AC power. Cependant, divers facteurs peuvent entraîner des fluctuations de tension. L'identification de ces causes est essentielle pour dépanner et garantir la fiabilité du système.. Une cause fréquente de fluctuation de tension est un mauvais câblage. Un câblage inadéquat ou ancien peut gêner le flux d’électricité, conduisant à une sortie de tension irrégulière. Ce problème est souvent négligé mais peut avoir des impacts importants sur la stabilité électrique. En plus, les circuits surchargés sont un autre coupable. Quand trop d’appareils consomment de l’énergie en même temps, l'onduleur peut avoir du mal à maintenir une sortie constante. Cela peut entraîner des pics ou des chutes de tension, affectant les appareils connectés. Certaines causes fréquentes de fluctuation de la tension de l'onduleur comprennent: Faulty or loose connections Environmental factors like humidity Inadequately sized inverters Environmental factors also play a role. Des températures et une humidité élevées peuvent altérer les performances de l'onduleur, provoquant des incohérences de tension. Il est important de prendre en compte ces influences externes lors du diagnostic des problèmes de tension.. Souviens-toi, certains onduleurs peuvent simplement être sous-dimensionnés pour la demande de puissance. Si l'onduleur n'est pas correctement adapté à la charge, cela peut entraîner des fluctuations. La mise à niveau vers un onduleur de taille appropriée peut atténuer ce risque. L'onduleur peut-il provoquer une fluctuation de tension?... Continue reading

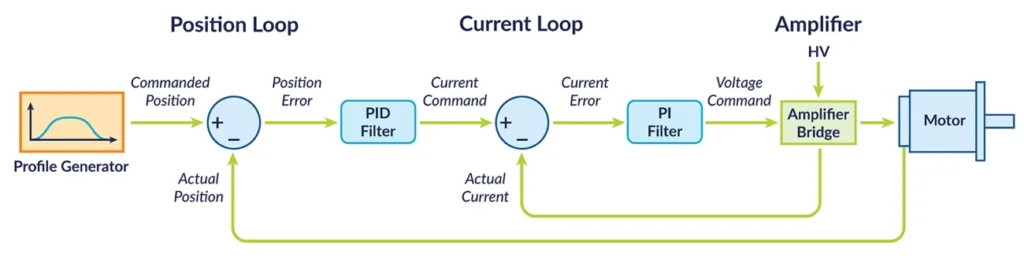

Si vous travaillez dans l'automatisation ou la robotique, vous savez que les contrôleurs de servomoteurs sont les héros méconnus derrière chaque mouvement précis du moteur. Mais quoi exactement... Continue reading

Showing 1–10 of 15 posts