Blog

Servo Drive Controller Guide Mastering Precision Motion Control

If you work in automation or robotics, you know that servo drive controllers are the unsung heroes behind every precise motor movement. But what exactly makes these controllers tick, and why are they crucial for delivering spot-on performance in today’s high-speed production lines? In this post, you’re going to uncover the core functions of servo drive controllers, how they differ from basic motor drives, and why mastering them can transform your motion control systems. Whether you’re troubleshooting, upgrading, or just curious, stick around—this guide is your shortcut to smarter, smoother automation.

The Fundamentals: What Is a Servo Drive Controller and How Does It Differ from Other Motor Controls?

A servo drive controller is the brain and muscle behind precise motor movement in industrial automation. Unlike basic motor controls that simply start and stop a motor or control speed, a servo drive controller manages position, speed, and torque with exceptional accuracy. Think of it as a highly skilled autopilot for motors—constantly adjusting to keep the system exactly on track.

Core Components Breakdown

At its heart, a servo drive controller includes:

- Power Stage: Supplies and regulates power to the servo motor.

- Control Circuitry: Processes commands and feedback signals.

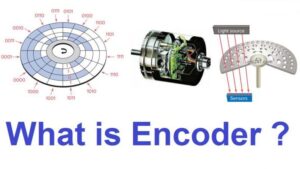

- Feedback Interface: Connects to encoders or resolvers that report the motor’s position and speed.

- Communication Module: Links to industrial networks or higher-level controllers.

Operational Principles

The key to servo controllers is their use of closed-loop control systems. This means the controller constantly monitors real-world motor behavior through feedback and adjusts output in real-time to correct errors. Imagine steering a car using GPS data combined with steering wheel adjustments—that’s how a servo drive maintains precision.

Key Differentiators

- Precision: Servo drive controllers deliver repeatable, smooth motion ideal for CNC machines, robotics, and packaging.

- Dynamic Response: Rapid acceleration and deceleration without losing control.

- Configurability: Programmable for various applications, from small servo motors to heavy industrial systems.

- Energy Efficiency: Features like regenerative braking return energy to the system, cutting costs.

DUOMI Spotlight

DUOMI’s servo drive controllers stand out by combining robust build quality, easy-to-use software tools, and integrated EtherCAT servo integration for seamless multi-axis system control. Their smart PID tuning options simplify complex setups, making optimal performance accessible for all skill levels. Whether upgrading legacy machinery or designing new automation solutions, DUOMI strikes the perfect balance of power, precision, and affordability.

How Servo Drive Controllers Work: A Deep Dive into the Control Loop

At the heart of every servo drive controller is a closed-loop control system that ensures precise, responsive motor operation. Here’s how it works:

- Signal Flow: The controller receives a command signal (position, speed, or torque) from the user or automation system. This input is processed and sent as a power output to the servo motor driver, which powers the motor accordingly.

- Feedback Mechanisms: A critical part of the system is the feedback encoder attached to the motor shaft. It continuously measures real-time position or speed and sends this data back to the controller. This constant feedback allows the controller to detect any deviation from the desired motion and make corrections instantly.

- Advanced Algorithms: Most modern servo motor controllers use PID (Proportional-Integral-Derivative) algorithms for precise tuning of how the motor responds to the feedback signals. Some use adaptive or model-based control strategies to handle more complex motions or multi-axis systems, improving accuracy and reducing settling times.

- Troubleshooting Essentials: When issues arise—like motor stalls, overshooting, or jittery motion—checking the feedback encoder health and re-tuning PID parameters are key first steps. Many programmable servo controllers offer diagnostic software tools to monitor signal integrity, detect faults, and optimize performance effectively.

Understanding these elements will help you get the most out of your servo drive system, especially in industrial automation motion control setups. For more advanced integration, consider options with EtherCAT servo integration for smoother communication and faster response times.

If you’re interested in components that work seamlessly with these systems, check out our range of industrial automation controls designed to complement servo drive controllers perfectly.

Types of Servo Drive Controllers: Choosing the Right Fit for Your Application

When selecting a servo drive controller, the first step is matching it to your motor type. Controllers vary based on compatibility with brushless DC servo controllers, AC servo motors, or traditional DC servo motor controllers. Knowing your motor’s requirements helps you pick a controller designed for optimal performance and efficiency.

Form factor matters too. Compact controllers are great for small servo motors and drives in tight spaces, while larger units suit industrial setups requiring higher power. Some units come as standalone drives; others integrate directly into larger systems like multi-axis servo systems.

Communication protocols also play a key role. Modern servo drives often support EtherCAT servo integration, Modbus, or CANopen, enabling smooth data exchange in automated environments. This is crucial for applications like CNC machines where precise, real-time control is mandatory.

DUOMI offers a range of servo drive controllers tailored for different needs—from compact, programmable options to high-end industrial-grade units. For example, their lineup includes controllers compatible with top-tier industrial automation standards, helping you future-proof your setup. Check out their offerings, like the Pro-face PFXGP4601TAD for versatile, reliable control in complex automation environments.

Quick Guide to Choosing Your Servo Drive Controller:

- Motor compatibility: Brushless DC, AC servo, or DC servo motors

- Form factor: Size and power needs based on application scale

- Communication: EtherCAT, Modbus, or CANopen for seamless integration

- DUOMI options: Range from compact to industrial — fit your budget and specs

Selecting the right controller sets the foundation for a smooth, efficient motion control system tailored to your specific needs.

Applications and Industry Use Cases: Where Servo Drive Controllers Shine

Servo drive controllers play a crucial role across many industries thanks to their precision, speed, and reliability. You’ll find them at the heart of industrial automation motion control systems in manufacturing plants where exact motor positioning and smooth operation are key. Industries like automotive assembly, robotics, packaging, and CNC machining heavily rely on servo motor drivers to keep production running efficiently.

Emerging trends show a growing demand for multi-axis servo systems used in complex applications such as 3D printing, semiconductor manufacturing, and medical devices. Thanks to their scalability, these controllers work just as well for small servo motors and drives in compact machines as they do in large-scale industrial setups.

Businesses investing in servo drive controllers can expect a strong return on investment, thanks to reduced downtime, energy savings through features like regenerative braking, and improved product quality. For those evaluating options, using an ROI calculator that factors in efficiency gains and maintenance savings can make choosing the right system easier.

For quality servo drive options, you might explore trusted brands available on platforms like the CNC Domi product catalog to find controllers tailored for your application needs.

Selecting and Integrating a Servo Drive Controller: Step-by-Step Best Practices

Picking the right servo drive controller comes down to a few key steps. Start with sizing criteria—match the controller to your servo motor’s power, torque, and speed needs. Undersized controllers cause performance issues, while oversized ones can waste money and space.

Next, run through a compatibility checklist. Ensure the controller supports your motor type (like brushless DC servo controllers or AC servo motors) and works with your system’s communication protocols (EtherCAT servo integration is popular for industrial automation motion control). Don’t forget to check encoder compatibility and feedback resolution requirements to keep that closed-loop control system running smoothly.

When it comes to installation, follow the manufacturer’s guidelines closely to ensure proper wiring, grounding, and cooling. Proper physical setup reduces troubleshooting down the line. Look for controllers with user-friendly mounting options and protection features against voltage spikes or overheating.

Finally, leverage the available software tools for programming, configuration, and PID tuning for servos. These tools simplify setup and make it easier to optimize performance or update firmware over time.

For reliable hardware and software options tailored to CNC systems, consider high-quality assemblies like the Fanuc α Series AC Servo Motor for seamless integration.

By following these steps, you’ll ensure your servo drive controller is the perfect fit and ready to deliver precise, efficient motion control.

Optimizing Performance: Tuning, Maintenance, and Advanced Features

Getting the most out of your servo drive controller means focusing on smart tuning, regular maintenance, and taking advantage of advanced features that boost efficiency and reliability. Here’s how to keep your system running smoothly and at peak performance.

Tuning Techniques for Servo Drive Controllers

Proper tuning fine-tunes the control loop to improve precision and response time. Key approaches include:

- PID Tuning for Servos: Adjust proportional, integral, and derivative gains to minimize overshoot and steady-state error.

- Adaptive Tuning: Some modern controllers adapt in real time to load changes, improving stability.

- Encoder Resolution Check: High-resolution feedback improves accuracy—match tuning to your encoder specs.

| Tuning Aspect | What to Adjust | Benefit |

|---|---|---|

| Proportional Gain (P) | Response speed | Faster response, risk of oscillation |

| Integral Gain (I) | Steady-state accuracy | Eliminates offset errors |

| Derivative Gain (D) | Overshoot damping | Smoother stops and starts |

Maintenance Strategies

Keeping your servo motor drivers and drives well-maintained prevents downtime:

- Regular Inspections: Check cables, connectors, and cooling fans.

- Firmware Updates: Update controller software to fix bugs and add features.

- Cleaning: Remove dust and debris from drive units to prevent overheating.

- Monitor Feedback Devices: Ensure encoders and resolvers function without errors.

Cutting-Edge Enhancements with DUOMI Edge

DUOMI offers advanced features that enhance the servo drive controller experience:

- Regenerative Braking: Recovers energy during deceleration, improving efficiency.

- Multi-axis Synchronization: Supports complex CNC machine servo drives and multi-axis setups.

- EtherCAT Servo Integration: Seamless communication protocol for faster, reliable motion control.

- Programmable Servo Controllers: Customize motion profiles with user-friendly software tools.

For best results, consider models like the Lenze EVS9322 EIV004 drive which integrate many of these features, especially for industrial automation motion control applications.

Optimizing your servo drive controller isn’t just about setting it once—ongoing attention to tuning and care extends the life and boosts the ROI of your system. Keeping these tips in your toolkit will help your setup perform reliably in the long run.