Blog

What Does an Encoder Do Explained | Types Functions and Uses

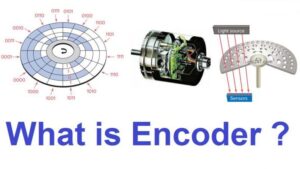

What Is an Encoder? – Simple Definition

An encoder is a device that converts motion — specifically position, speed, or direction — into electrical signals. Think of it as the “eyes” of a motor or automation system, providing crucial feedback that helps machines know exactly where and how fast something is moving.

At its core, an encoder measures:

- Position: Where the shaft or axis is located.

- Speed: How fast it’s spinning.

- Direction: Which way it’s turning.

This data is essential for precise control, especially in robotics, CNC machines, and servo systems.

Encoder vs. Sensor: What’s the Difference?

It’s common to confuse encoders with sensors, but here’s the quick distinction:

| Feature | Encoder | Sensor |

|---|---|---|

| Function | Provides position/speed feedback | Detects presence or physical changes (like temperature, pressure) |

| Output Type | Electrical signals representing motion | Usually binary on/off signal or analog value |

| Examples | Rotary encoder, linear encoder | Proximity sensor, temperature sensor |

Encoders are a specific type of sensor focused on motion measurement, offering precise data rather than just detection.

Practical takeaway: An encoder acts like a motor’s eyes, helping machines “see” their movement for precise control. Remember, all encoders are sensors, but not all sensors are encoders!

How Does an Encoder Actually Work?

Encoders work by converting mechanical motion—like rotation or linear movement—into electrical signals that machines can understand. There are three common types based on how they sense movement: optical, magnetic, and capacitive.

- Optical encoders use a disk with patterns and a light source. As the disk spins, sensors detect light passing through or being blocked, creating pulses.

- Magnetic encoders rely on magnetic fields and sensors to detect the position of a magnet attached to a moving part.

- Capacitive encoders measure changes in capacitance caused by movement between conductive plates.

Step-by-Step Signal Generation

- The rotating part moves the encoder’s disk or sensor ring.

- The sensor detects changes in light, magnetic field, or capacitance.

- These changes are turned into electrical pulses—regular on/off signals as the part moves.

- The pulses are sent as output signals to controllers or motors for position or speed feedback.

Pulses and Channels Explained

Encoders often produce multiple signals:

- Channel A and Channel B: These are two pulse trains offset by 90 degrees, working together in what’s called quadrature signaling. This allows the system to detect not just movement, but the direction too, by comparing which signal leads or lags.

- Z channel (or index pulse): This gives one pulse per revolution, marking a precise reference point for calibration.

This pulse pattern lets machines track exact position and speed with high accuracy.

For a practical example, check out how sensors like the SICK DT35 series use these principles in an industrial setting.

The Two Main Types of Encoders You Need to Know

When it comes to encoders, there are two primary types you should know: incremental encoders and absolute encoders. Each serves a special role depending on your application needs.

Incremental Encoders

Incremental encoders work by generating a stream of pulses as the shaft turns. These pulses are counted to determine position, speed, and direction. Think of them like a digital odometer: they count increments but don’t remember the exact position when powered off.

- How they work: They emit pulses corresponding to movement increments. A controller counts these pulses to track position.

- Pros:

- Cost-effective and widely used

- High-speed operation suitable for fast motors

- Cons:

- Position info is lost when power drops or system restarts

- Often need a homing routine to reset position

- Typical resolution: Pulses per revolution (PPR) varies by model and application—from a few hundred to several thousand pulses.

Absolute Encoders

Unlike incremental versions, absolute encoders provide a unique digital code for each shaft position, even immediately after power loss. They’re the “memory” version of encoders.

- Single-turn vs Multi-turn:

- Single-turn encoders record precise position within one rotation.

- Multi-turn encoders track multiple rotations using internal counters.

- How they work: They output a distinct code—using methods like Gray code, binary, or communication protocols such as SSI, BiSS, or EnDat—indicating the exact angle.

- Pros:

- Never lose position data, making them ideal for safety-critical or mission-critical systems

- Simplify system startup since position is always known

- Cons:

- Typically more expensive than incremental encoders

Choosing between incremental and absolute depends on if your system needs to remember position after power-off and your budget constraints. For heavy industrial use, especially in robots or CNC machines, absolute encoders are often preferred for reliability and precision.

For more details on encoders suitable for industrial automation, check out reliable options like Heidenhain encoders designed for high precision and durability.

Where Are Encoders Used? Real-World Applications

Encoders play a critical role in a wide range of industries where precise motion control is essential. In industrial robotics and cobots, they provide accurate position feedback that allows arms and tools to move smoothly and repeatably, improving both safety and productivity.

In CNC machines and machining centers, encoders track the cutting tool’s exact position to ensure high-precision manufacturing. This is crucial for parts that require tight tolerances. If you are working with motors in such setups, pairing them with reliable encoders like those used in ABB drives enhances the overall performance and agility of your system.

Servo motors depend heavily on encoders for feedback control loops, helping maintain exact speed and position, which is vital in automation and packaging lines.

Encoders are also found in large-scale applications like elevators, cranes, and wind turbines, where they monitor shaft rotation and position to prevent mechanical failure and optimize efficiency.

In the medical field, these devices are built into precision instruments and diagnostic machines where precise, repeatable motion is life-critical.

Finally, the rise of electric vehicles and e-mobility solutions relies on encoders to manage motor control and battery efficiency, driving better performance and extended range.

Across these diverse applications, encoders ensure systems work with reliability and precision, making them indispensable in today’s technology-driven world.

Key Benefits of Using Encoders in Motion Systems

encoder benefits in motion control systems

Encoders play a crucial role in improving motion systems by providing precise position and velocity feedback. Here’s why they’re essential:

-

Precise Position and Velocity Control

Encoders convert mechanical motion into electrical signals, allowing systems to know exactly where something is and how fast it’s moving.

-

Improved Repeatability and Accuracy

With an encoder, machines can return to the same position repeatedly with minimal error, which is vital in CNC machining and automation.

- Closed-Loop vs Open-Loop Control

| Control Type | Description | Encoder Role |

|---|---|---|

| Open-Loop | Commands sent without feedback | No encoder needed |

| Closed-Loop | Feedback used to adjust motion | Encoder provides real-time data |

Encoders enable closed-loop systems to constantly adjust for errors, leading to smoother and more reliable motion.

- Energy Efficiency and Reduced Wear

By accurately controlling motion, encoders help motors avoid overworking, which saves energy and extends the life of mechanical parts.

Using an encoder, such as those integrated in popular servo motors or industrial drives like the Siemens motor 1F1FK7063, ensures your system runs smarter and longer.

Incremental vs Absolute – Quick Comparison Table

| Feature | Incremental Encoder | Absolute Encoder |

|---|---|---|

| Position Tracking | Needs power to maintain position | Maintains exact position without power |

| Output | Pulses (counts motion steps) | Unique position value (digital code) |

| Resolution | Pulses per revolution (PPR) | Depends on bits (can be very high) |

| Power Loss Impact | Position lost on power down | Position retained permanently |

| Cost | Generally lower | Typically higher |

| Speed | High speed, good for fast motion | Slightly slower, but precise |

| Use Cases | Basic motion control, cost-sensitive | Safety-critical, precise position feedback |

| Signal Type | Quadrature signals (A, B, Z) | Digital output (SSI, BiSS, EnDat protocols) |

Both types of encoders play a vital role in motion systems. Your choice depends on factors like accuracy needs, budget, and if you require position retention after shutdown. For applications like CNC machines or servo systems, incremental encoders offer fast, cost-effective control, while absolute encoders excel where safety and exact position are critical.

For more about motion control components, see the Fanuc I/O unit product details that often integrate with encoders in industrial setups.

Optical vs Magnetic Encoders – Which One Wins?

When choosing an encoder, the decision often comes down to optical vs magnetic encoders, each with its strengths and weaknesses. Here’s a simple breakdown to help you decide:

| Feature | Optical Encoders | Magnetic Encoders |

|---|---|---|

| Accuracy & Resolution | Very high (fine lines on discs) | Moderate but improving |

| Durability | Sensitive to dust, dirt, and moisture | Excellent in harsh, dirty environments |

| Cost | Usually more expensive | Generally more cost-effective |

| Speed | High-speed capability | Good, but not always as fast |

| Typical Use | Clean, controlled environments (e.g., CNC machines) | Industrial automation, outdoor and heavy-duty settings |

When to Choose a Magnetic Encoder

Magnetic encoders are the go-to option when your project faces extreme conditions such as:

- Dusty or dirty environments

- Vibration and shock exposure

- Moisture or water splash

- Temperature fluctuations

Because magnetic encoders rely on magnetic fields rather than light, they are inherently more rugged and reliable under these harsh conditions. For example, if you’re working with industrial robotics or outdoor wind turbines, magnetic encoders are often the better choice.

On the other hand, if your system demands ultra-precise feedback in a clean environment, like a servo motor feedback system, optical encoders shine.

For a practical example of a high-quality magnetic encoder, check out the Mitsubishi Absolute Encoder TS5691N1170 that combines durability with accuracy.

Choosing between optical and magnetic encoders largely depends on your application’s environment, budget, and precision needs.

How to Choose the Right Encoder for Your Project

Picking the right encoder can be tricky, but focusing on a few key factors makes it easier. Here are 7 practical criteria to help you decide:

| Selection Criteria | What to Consider |

|---|---|

| Resolution | Determines accuracy — higher Pulses Per Revolution (PPR) means finer control. |

| Environment | Harsh or dirty? Choose magnetic or ruggedized optical encoders. |

| IP Rating | Needed for dust or water resistance; typical ratings are IP65, IP67, or higher. |

| Speed | Ensure the encoder supports your system’s max RPM without signal loss. |

| Output Type | Match signals like quadrature, SSI, or analog to your controller or PLC. |

| Size & Mounting | Consider space constraints and mounting style (shaft or hollow). |

| Budget | Balance cost versus required features and durability. |

Quick Encoder Selection Checklist

- Confirm your required resolution (PPR or bits)

- Check if the environment calls for optical or magnetic type

- Verify IP rating for protection needs

- Match output signals with your existing system requirements

- Confirm physical size fits your machine design

- Determine maximum shaft speed rating

- Set a realistic budget based on encoder specs

For tighter integration with CNC machines or automation setups, look at encoder options compatible with popular systems like SIMATIC controllers — for example, the Siemens Display 6AV2124-0MC01-0AX0 helps visualize feedback from encoders in real time.

Using these guidelines will help ensure your chosen encoder delivers precision, reliability, and long-term performance for your specific project needs.

Common Myths and Misconceptions About Encoders

encoder myths and facts explained

Encoders are essential in motion control, but several myths can confuse buyers and users. Let’s clear up some common misconceptions:

-

“Higher PPR is always better.”

Pulses Per Revolution (PPR) determines an encoder’s resolution, but more pulses don’t always mean better performance. Extremely high PPR can add noise to the signal and increase processing demands, which might not be necessary for your application. Choose a PPR that matches your system’s accuracy needs without overcomplicating things.

-

“Absolute encoders are too expensive for most applications.”

While absolute encoders typically cost more than incremental types, their benefits—like never losing position after power loss and enhanced safety—can save money in the long run by reducing downtime and maintenance. For critical systems, the investment is often worth it.

-

“Resolvers are the same as encoders.”

Resolvers and encoders both provide position feedback but work differently. Resolvers use analog signals and are highly robust in harsh environments, while encoders output digital pulses with higher resolution options. Knowing the differences can help pick the right device for your project.

Understanding these points helps make smarter choices when selecting motor encoders or position feedback devices. For example, if you’re looking for reliable Yaskawa motor encoder options or need solutions that suit demanding industrial environments, it’s wise to consider these facts upfront.

The Future of Encoder Technology

Encoder technology is evolving fast to meet the demands of modern automation and precision control. One major trend is miniaturization, making encoders smaller and lighter without sacrificing accuracy. This is critical for compact robotics, drones, and embedded systems where space is tight.

At the same time, on-axis designs are becoming popular. These encoders fit directly onto the motor shaft, reducing mechanical connections and improving reliability. On-axis encoders cut down installation complexity and offer excellent feedback, which is great for tighter motion control in machinery.

Another exciting development is the rise of IO-Link and single-cable solutions. These simplify wiring by combining power, data, and signal transmission into one cable. IO-Link enables smart communication with control systems, allowing easier setup, diagnostics, and maintenance—a big plus for industrial users optimizing uptime.

Lastly, integrated bearingless encoders promise longer life and less friction. By eliminating the encoder bearing, these designs reduce wear and maintenance while maintaining precise position feedback.

All these advances position encoders to be smarter, more compact, and easier to integrate—perfect for the future of automation, robotics, and advanced manufacturing.

For advanced industrial applications, exploring options like the Siemens SKP15 encoder can provide cutting-edge performance that aligns with these emerging technologies.