Blog

Expert Tips for Choosing and Using Servo Motors and Joysticks

If you’re gearing up to bring precise motion control to your next project, knowing how to choose and use servo motors and joysticks can make all the difference. Whether you’re building a robotic arm, crafting an interactive device, or fine-tuning an automation prototype, picking the right components and integrating them smoothly is key to avoiding headaches like motor stalls or erratic control. In this guide, you’ll get straightforward, expert recommendations for selecting the perfect servo motors and joysticks, plus practical tips for wiring, calibration, and optimising performance—everything you need to get your system moving with confidence and precision. Let’s jump straight into the essentials to elevate your DIY build or engineering endeavour!

Understanding Servo Motors: Fundamentals and Types

When choosing a servo motor, it’s crucial to understand the basics to make informed decisions. At their core, servo motors are rotary or linear actuators equipped with feedback mechanisms—usually encoders or potentiometers—that continually monitor position, speed, and torque. This feedback allows precise control, essential for robotics, automation, and hobby projects alike.

Rotary vs. Linear Servo Motors

- Rotary servos are the most common, rotating shafts to specific angles. Think of robotic arms, pan-tilt camera mounts, or RC models.

- Linear servos move objects along a straight path. They’re ideal for sliding doors, valve controls, or precise linear positioning.

Understanding your application helps determine whether rotary or linear motion is best suited.

AC vs. DC Servos: Torque and Efficiency

- AC servo motors usually provide higher torque at faster speeds and better thermal performance, making them ideal for industrial automation.

- DC servos, commonly found in hobby and lightweight applications, offer ease of control and high torque-to-size ratios but can be less efficient in heavy-duty tasks.

Each type has trade-offs between speed, torque, efficiency, and complexity.

Hobby-Grade vs. Industrial-Grade Servos

- Hobby-grade servos are affordable and compact but may lack the durability for sustained heavy use.

- Industrial-grade servos, such as those in the domi servo lineup, offer enhanced reliability, advanced feedback options, and rugged construction suited for demanding environments.

Whether you’re crafting a DIY robotics project or equipping a professional automation system, domi’s range covers from entry-level to premium industrial servos, providing a balanced choice between cost, performance, and longevity.

Key Recommendations for Choosing the Right Servo Motor

Selecting the right servo motor starts with a clear, step-by-step process that matches your application’s specific needs. First, assess the primary demands like load weight, required acceleration, and the environment—whether it’s indoor, dusty, or humid. These factors shape your motor choice dramatically.

Next, perform torque and speed calculations, factoring in the inertia ratio to ensure smooth, responsive motion. Keeping the inertia ratio within recommended limits reduces overshoot and improves control. Consider motor size and mounting options carefully, as proper installation affects both performance and longevity. Don’t overlook gearhead options, which can optimise torque output without sacrificing speed.

Feedback devices such as encoders, resolvers, or potentiometers play a critical role in accuracy and control stability. Choosing the right feedback type depends on your precision requirements and system complexity.

Avoid common pitfalls like undersizing the servo or misreading specs; tools like domi’s sizing calculator can help simplify this. Balancing your budget against performance is essential—domi’s lineup spans from entry-level choices to premium servo motors, allowing you to pick a solution that fits both your project and financial plan.

For detailed technical advice and choosing the best match, explore domi’s dedicated technical resources and product range to find tailored servo motor solutions.

Demystifying Joysticks: Types, Specs, and Selection Criteria

Choosing the right joystick starts with understanding the main types: analog and digital. Analog joysticks provide smooth, continuous signals, ideal for precise control, while digital joysticks offer simple on/off directions, better suited for straightforward commands. This sensing difference affects precision, so pick based on how finely you need to control your servo systems.

Ergonomics also matter. Thumbsticks are compact and convenient for casual use or handheld devices, whereas full-hand joysticks offer better grip and comfort for extended operation, common in industrial or robotics setups.

Wired versus wireless is another key decision. Wired joysticks typically have lower latency and no battery worries, making them reliable for time-critical applications. Wireless options add freedom but may introduce slight delays and require power management—crucial if you value uninterrupted control or portability.

When selecting a joystick, focus on resolution (higher counts mean finer movement detection), force feedback (for a more tactile experience), and durability, especially if the device will see heavy use. Compatibility with microcontrollers like Arduino is a must-have for hobbyists and developers; thankfully, many domi joystick modules come ready with smooth interfacing and anti-drift technology, which helps maintain accurate neutral positions over time, preventing erratic servo commands.

For detailed options, explore domi’s joystick modules that balance precision and robustness, perfect for integrating into your motion control projects.

Interfacing Joysticks with Servo Systems

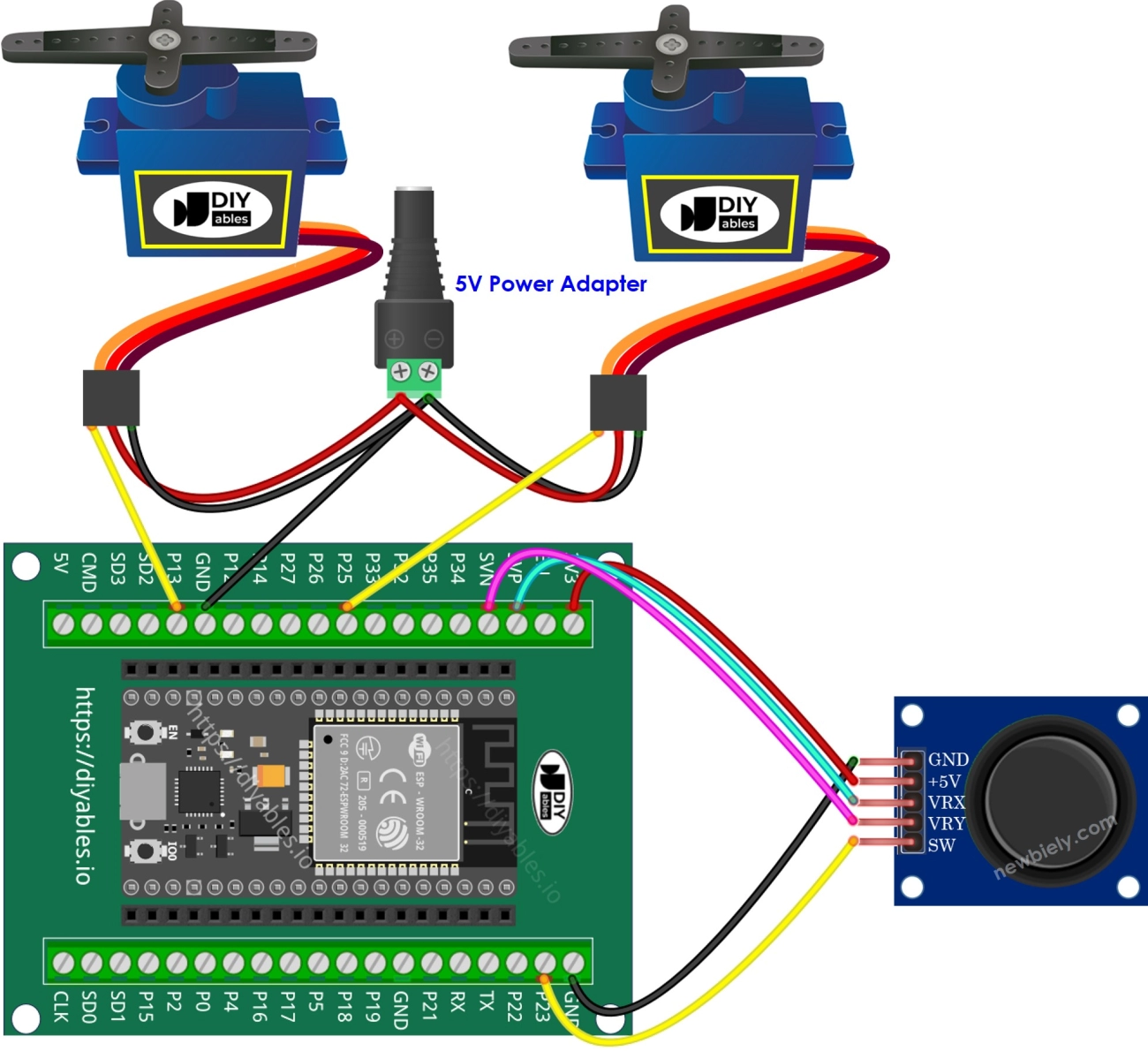

Connecting joysticks to servo motors requires a good grasp of hardware essentials. Start by understanding pinouts for your joystick and servo—matching the correct signal, power, and ground pins is vital to avoid damage. Always check voltage compatibility; most hobby servos and joysticks run on 5V, but double-check specs to prevent mismatches.

When wiring, keep cables short and tidy to reduce noise. For single servo setups, a simple three-wire connection (signal, power, ground) suffices, while dual servo or pan-tilt systems require wiring for each servo plus common power and ground lines. Clear wiring diagrams can help ensure correct connections and ease troubleshooting.

In terms of motion control, servo motors are typically driven by PWM (Pulse Width Modulation) signals, where the pulse width determines the servo shaft angle. Joysticks usually output an analog voltage proportional to their position; this needs to be mapped correctly to the servo’s PWM range. The Arduino IDE makes this straightforward, with plenty of libraries and example code available.

Key code practices include:

- Deadzone calibration: filtering out minor joystick jitters around the centre to stop servo flicker.

- Jitter smoothing: averaging input values or applying low-pass filters to create smooth, stable motion.

For more advanced control, multi-axis setups benefit from drivers like the domi servo drivers, which handle multiple servos with precise synchronisation and smooth motion profiles, ideal for robotic arms or camera gimbals.

For practical examples and digital output modules to complement your servo control, consider integrating solutions like the Siemens Simatic S7-1200 digital output module, which offers robust hardware interfacing options for industrial-grade projects.

Practical Usage and Best Practices

Starting with a beginner project, a simple setup where a single joystick controls one servo motor is ideal. This involves wiring the joystick to an Arduino, connecting the servo signal wire to a PWM pin, and writing straightforward code to map joystick movements to the servo’s position. A clear schematic helps ensure smooth initial testing, especially for those new to joystick servo interfacing.

For an intermediate project, try a dual-servo pan-tilt camera mount controlled by a joystick. This setup allows independent control of horizontal and vertical movements, improving usability in applications like remote surveillance or photography. The wiring is a bit more complex, requiring careful voltage matching and pin assignments. This stage sharpens skills in motion control calibration and introduces basic multi-axis coordination.

In professional deployments, focus on fine-tuning calibration for precise response, managing power effectively to avoid voltage drops, and thorough testing to ensure reliability under varying operating conditions. Tools like PID tuning adjusted to your servo’s inertia ratio can significantly boost performance. Consistent maintenance protocols and emergency stop mechanisms also enhance safety and longevity.

A great example of practical success is domi’s servo kits used in RC drone controllers, known for their high response accuracy and durability. These kits demonstrate what’s achievable by combining quality industrial-grade servos with robust joystick modules and anti-drift technology, making them perfect for demanding UK users pushing the limits of hobby and professional applications.

For detailed motor control components to support advanced setups, consider exploring options like the Fanuc CNC control system circuit board which can provide sophisticated interfacing and reliability.

Troubleshooting and Optimization

When working with servo motors and joysticks, a few common issues can crop up that affect performance and reliability:

- Jitter: This often results from signal noise or incorrect pulse-width modulation (PWM) settings. Check your wiring for loose connections and ensure clean power supply filtering. Using shielded cables can reduce interference.

- Gear Stripping: Overloading the servo beyond its torque limits can damage gears. Avoid this by correctly sizing your servo using inertia ratio calculations and opting for high-torque models when necessary.

- Signal Noise: Electrical noise can distort encoder feedback or joystick inputs, causing erratic movements. Proper grounding and adding ferrite beads can help cleanse signal lines.

To optimise performance, focus on PID tuning—adjusting proportional, integral, and derivative gains to smooth movements and reduce overshoot. Matching the servo’s inertia to the application’s load is critical for precise control and avoiding mechanical strain.

Regular maintenance is key to longevity:

- Lubricate gears and moving parts as recommended by the manufacturer.

- Keep firmware updated to benefit from improved control algorithms.

- Consider component upgrades when operating conditions exceed original specs.

Finally, always prioritise safety. Integrate overcurrent protection to prevent damage during stall conditions and plan for emergency stops in your control logic to mitigate hazards.

For further insights on integrating safety devices as part of your servo system, see the range of non-contact safety sensors designed to enhance operational security.